Saving a 1980 750 twin.

- DoctoRot

-

Topic Author

Topic Author

- Offline

- Sustaining Member

- Oh, the usual... I bowl, I drive around...

- Posts: 2564

- Thanks: 701

Re: Saving a 1980 750 twin.

24 Jan 2016 20:34 - 24 Jan 2016 21:31

The project bikes are back in storage for a few months but i kept a couple parts for to me to work on until I get a garage again. The lathe that i have access to just got rebuilt so i thought id finally machine a couple simple things on this to get started, as my skills progress I will attempt some more complicated stuff. I remade one of the front wheel spacers out of 7075, waiting on some stock to make a speedo plug for the LH side.

I also turned a starter plug for the case; because the starter motor leaves this big gap on the front of the motor I really want to put an oil cooler there, so I drilled and tapped two holes on the outside of the plug to help with the cooler mounting down the road.

I cut off the factory gauge mounts and polished it out.

I got a Speedhut GPS speedo and tach. Nothin fancy on the gauge face but i but for about $20 extra they will give you a template and they will print whatever you want on a gauge face, so I designed my own.

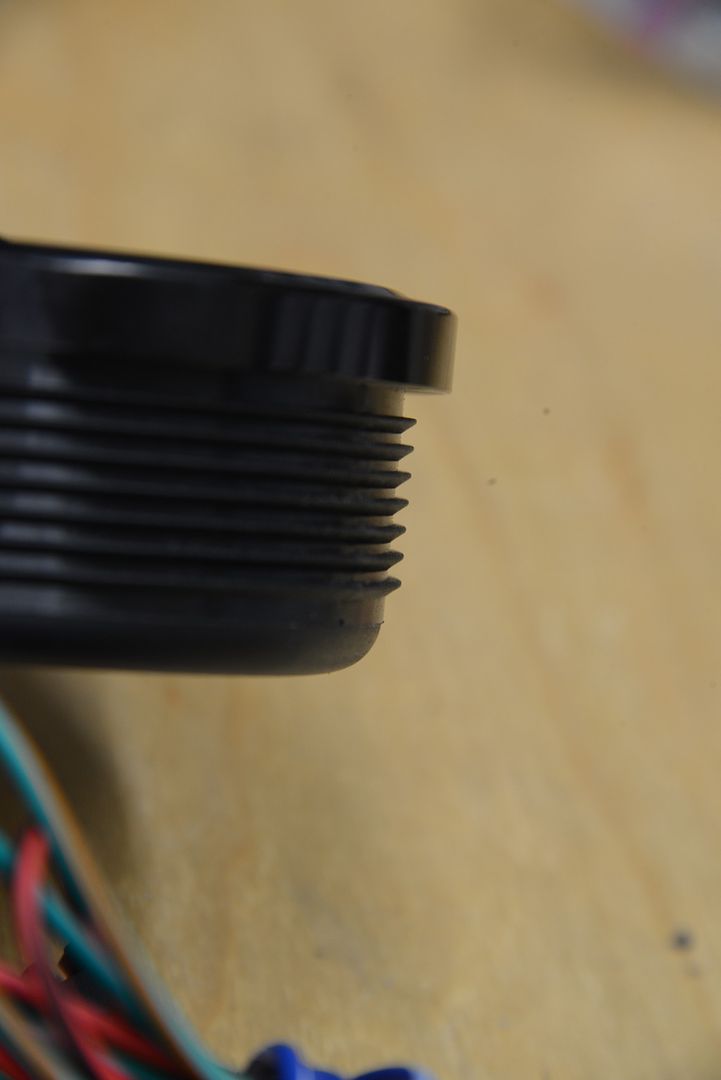

Im thinking about turning up a cover for the back of the gauge and want to try cutting threads in a tube. Do the machinists out there know what kind of thread this is or any tips on cutting ID threads?

Im gonna use this 63-74 sportster headlight with a custom composite bucket that i originally made for my 1000 project. I am kinda digging the old school diffuser but if i go HID or LED i will use the clear lens. I think the screws at the bottom of the rings are kinda crude. Any suggestions to make it looks a bit cooler? I was thinking about some type of clamp or something.

I just mocked it up real quick so i can start brainstorming ideas on how i want to tie this all together.

I also turned a starter plug for the case; because the starter motor leaves this big gap on the front of the motor I really want to put an oil cooler there, so I drilled and tapped two holes on the outside of the plug to help with the cooler mounting down the road.

I cut off the factory gauge mounts and polished it out.

I got a Speedhut GPS speedo and tach. Nothin fancy on the gauge face but i but for about $20 extra they will give you a template and they will print whatever you want on a gauge face, so I designed my own.

Im thinking about turning up a cover for the back of the gauge and want to try cutting threads in a tube. Do the machinists out there know what kind of thread this is or any tips on cutting ID threads?

Im gonna use this 63-74 sportster headlight with a custom composite bucket that i originally made for my 1000 project. I am kinda digging the old school diffuser but if i go HID or LED i will use the clear lens. I think the screws at the bottom of the rings are kinda crude. Any suggestions to make it looks a bit cooler? I was thinking about some type of clamp or something.

I just mocked it up real quick so i can start brainstorming ideas on how i want to tie this all together.

Last edit: 24 Jan 2016 21:31 by DoctoRot.

Please Log in or Create an account to join the conversation.

- 80B4

-

- Offline

- User

- Posts: 447

- Thanks: 105

Re: Saving a 1980 750 twin.

26 Jan 2016 03:45 - 26 Jan 2016 03:47

That is a Buttress thread profile. I've seen that used on old equipment (like a vise), it's interesting that it is being used in this application!

1980B4 1000

1978 Z1R

1978 B3 750

1978 Z1R

1978 B3 750

Last edit: 26 Jan 2016 03:47 by 80B4.

The following user(s) said Thank You: DoctoRot

Please Log in or Create an account to join the conversation.

- loudhvx

-

- Offline

- KZr Legend

- Posts: 10864

- Thanks: 1616

Re: Saving a 1980 750 twin.

26 Jan 2016 06:22

That is some amazing detail work. But I would be too paranoid to let that thing out of the house. It would have to sit in my living room. :laugh:

1981 KZ550 D1 gpz.

Kz550 valve train warning.

Other links.

Kz550 valve train warning.

Other links.

The following user(s) said Thank You: DoctoRot

Please Log in or Create an account to join the conversation.

- DoctoRot

-

Topic Author

Topic Author

- Offline

- Sustaining Member

- Oh, the usual... I bowl, I drive around...

- Posts: 2564

- Thanks: 701

Re: Saving a 1980 750 twin.

02 Feb 2016 20:41 - 02 Feb 2016 20:50

Just a quick update, I finally had a chance to hop on the lathe and turn up the speedo delete. In just these two small parts i shaved almost half a pound from the front end. I'm really enjoying messing around on the machines. I picked up a tool blank to grind into the profile for that buttress thread. I practiced on some brass and think i have the thread cutting thing figured out well enough to attempt the buttress thread.

Last edit: 02 Feb 2016 20:50 by DoctoRot.

Please Log in or Create an account to join the conversation.

- scubaanders

-

- Offline

- Sustaining Member

- Posts: 549

- Thanks: 234

Re: Re:Saving a 1980 750 twin.

03 Feb 2016 00:30

Spanking nice design on the speedo plug, I might steal you style right off.

/A

/A

Gpz750R1 1982

Gpz750A1 1983

Gpz1100A2 1984

FZ750 1985

Gpz900R -91

Gpz750A1 1983

Gpz1100A2 1984

FZ750 1985

Gpz900R -91

The following user(s) said Thank You: DoctoRot

Please Log in or Create an account to join the conversation.

- GPzMOD750

-

- Offline

- User

- Posts: 1365

- Thanks: 148

Re: Saving a 1980 750 twin.

03 Feb 2016 02:13

About the threading.... is that a metric or standard pitch? What machine will you be cutting on and is it set up for that pitch? Not all machines can cut both metric and standard and even if they can the gearing doesn't allow for all pitches. Butress threads are very tricky when doing ID make sure you have plenty of stock to redo if you don't get it the first time.

Where exactly are you threading?

Where exactly are you threading?

The following user(s) said Thank You: DoctoRot

Please Log in or Create an account to join the conversation.

- DoctoRot

-

Topic Author

Topic Author

- Offline

- Sustaining Member

- Oh, the usual... I bowl, I drive around...

- Posts: 2564

- Thanks: 701

Re: Saving a 1980 750 twin.

03 Feb 2016 21:04 - 03 Feb 2016 21:29

I believe it is a standard pitch of 6tpi, which the lathe has, it also has metric as well. I have enough aluminum for three attempts, im going to be threading the very end of a piece of 4" tube so i should be able to see whats going on.

Last edit: 03 Feb 2016 21:29 by DoctoRot.

Please Log in or Create an account to join the conversation.

- GPzMOD750

-

- Offline

- User

- Posts: 1365

- Thanks: 148

Re: Saving a 1980 750 twin.

06 Feb 2016 11:15Fingers crossed, make sure you don't get caught up in so much detail that you overlook something simple like doing the buttress profile backwards. Just a thought, never done that myself.DoctoRot wrote: I believe it is a standard pitch of 6tpi, which the lathe has, it also has metric as well. I have enough aluminum for three attempts, im going to be threading the very end of a piece of 4" tube so i should be able to see whats going on.

Seriously, it's one of those things that have a major sphincter pucker factor until you get it done. Then you say to yourself, "Piece of cake! I don't know why I thought it was a big deal."

Please Log in or Create an account to join the conversation.

- DoctoRot

-

Topic Author

Topic Author

- Offline

- Sustaining Member

- Oh, the usual... I bowl, I drive around...

- Posts: 2564

- Thanks: 701

Re: Saving a 1980 750 twin.

06 Feb 2016 19:42 - 06 Feb 2016 19:42most things on the lathe seem like this right now.GPzMOD750 wrote: "major sphincter pucker factor"

Last edit: 06 Feb 2016 19:42 by DoctoRot.

Please Log in or Create an account to join the conversation.

- DoctoRot

-

Topic Author

Topic Author

- Offline

- Sustaining Member

- Oh, the usual... I bowl, I drive around...

- Posts: 2564

- Thanks: 701

Re: Saving a 1980 750 twin.

11 Feb 2016 01:20 - 11 Feb 2016 01:22

Started working on the headlight ears by machining up these bits and welding em up. I made a sleeve out of aluminum to keep the tubes from going out of round while welding. now it's clear should have used steel for the sleeve because its stuck in the second. I'm going to slit them tomorrow on the mill and will cut through the sleeve too, hopefully that will help me get the sleeve out.

Last edit: 11 Feb 2016 01:22 by DoctoRot.

Please Log in or Create an account to join the conversation.

- SWest

-

- Offline

- Sustaining Member

- 10 22 2014

- Posts: 23257

- Thanks: 2840

Re: Saving a 1980 750 twin.

11 Feb 2016 04:44

Did you try freezing it?

Steve

Steve

Z1b1000 1975 Z1b

kzrider.com/forum/11-projects/598262-kz-...-will-it-live#672882

kzrider.com/forum/2-engine/597654-poser?start=240#704229

kzrider.com/forum/11-projects/598262-kz-...-will-it-live#672882

kzrider.com/forum/2-engine/597654-poser?start=240#704229

Please Log in or Create an account to join the conversation.

- 531blackbanshee

-

- Offline

- Vendor

- Posts: 7447

- Thanks: 798

Re: Saving a 1980 750 twin.

11 Feb 2016 08:42i believe i would not slit the sleeve,only the outter piece.as it will then spring open slighlty.

if you slit both the inner and outter they will both spring open and remain locked.

imho,

leon

skiatook,oklahoma 1980 z1r,1978 kz 1000 z1r x 3,

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

Please Log in or Create an account to join the conversation.